Robust design optimization and robust optimal control

Introduction

Practical application of the numerical optimization results is

difficult because of the fact that any complex technical system is a stochastic system

and the characteristics of this system have probabilistic nature. We would

like to emphasize that, speaking about the stochastic properties of

a technical system within the frame of optimization tasks, we imply that

the important parameters of any

system are stochastically spread. Normally it occurs during the production

stage despite of the up-to-date level of modern technology. Random

deviations of the system parameters lead to a random change in system efficiency.

An efficiency extreme value, obtained during the optimization problem

while solving in traditional (deterministic) approach, is simply a

maximum attainable value and can be considered as just conventional

optimum from the point of view of its practical realization. Thus, one

can consider two different types of optimization criteria. One of them

is an ideal efficiency which can be achieved under the conditions of

absolutely precise practical replication of the system parameters under

consideration. Other optimization criteria are of probabilistic nature. For example:

mathematical expectation of the efficiency; the total probability of assuring

preset constraints; variance of the efficiency and so on

It is evident that the extreme of the one of these criteria doesn't guarantee

the assurance of the high level of another one. Even more, these criteria

may contradict to each other. Thus, in this case we have a multicriteria

optimization problem.

Our concept

Our concept of robust design optimization and robust optimal control

allows to determine the optimal practical solution that could

be implemented with the high probability for the given technology level

of the production plants. Many modern probabilistic approaches either

employ the estimation of probabilistic efficiency criteria only at the stage

of the analysis of obtaining deterministic solution, or use significantly

simplified assessments of probabilistic criteria during optimization process.

The distinctive feature of our approach is that during robust design optimization

we solve the optimization problem involving direct stochastic formulation,

where the estimation of probabilistic criteria is accomplished at each iteration.

This procedure reliably produces fully robust optimal solution. High efficiency

of the robust design optimization is provided by the capabilities of IOSO

algorithms to solve stochastic optimization problems with large level

of noise.

Our robust design optimization concept provides considerable (several

orders of magnitude) reduction in cost and time during the development of

the new highly efficient systems. This concept also considerably (several

times) reduces risk associated with new technical solutions.

For example,

during optimal calibration of the automotive engine the development time

was reduced by 5 times, during development of the new axial compressor

more than 200 times. The most important feature of IOSO technology is

the ability to solve robust design optimization problems with the large

number of variables (hundreds) and efficiency criteria (dozens).

Real-life example

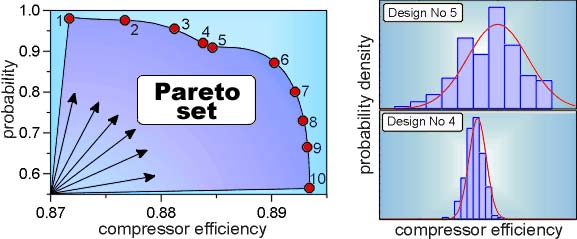

MULTICRITERIA ROBUST DESIGN OF THE MULTISTAGE AXIAL FLOW COMPRESSOR

Problem features: 140 design variables, 2 criteria.

The trade-off area:

the compressor efficiency grows from 0.87 up to 0.89

while

the implementation probability reduces from 0.97 down to 0.56 !

The solution N1 could be implemented with high probability, but it

has low efficiency. Solution N10 has high efficiency, but has the low

probability of practical implementation. The solutions N4 and N5 have

very similar efficiencies and probability of implementation, but N4 is

better, because it has lower level of efficiency distribution. It is the

solution (N4) that should be implemented in practice.

Back...

|